Need Help? Contact Us Trade Customer? Register / Login

We are now closed for the Ester Weekend.

We reopen on Tuesday 22nd.

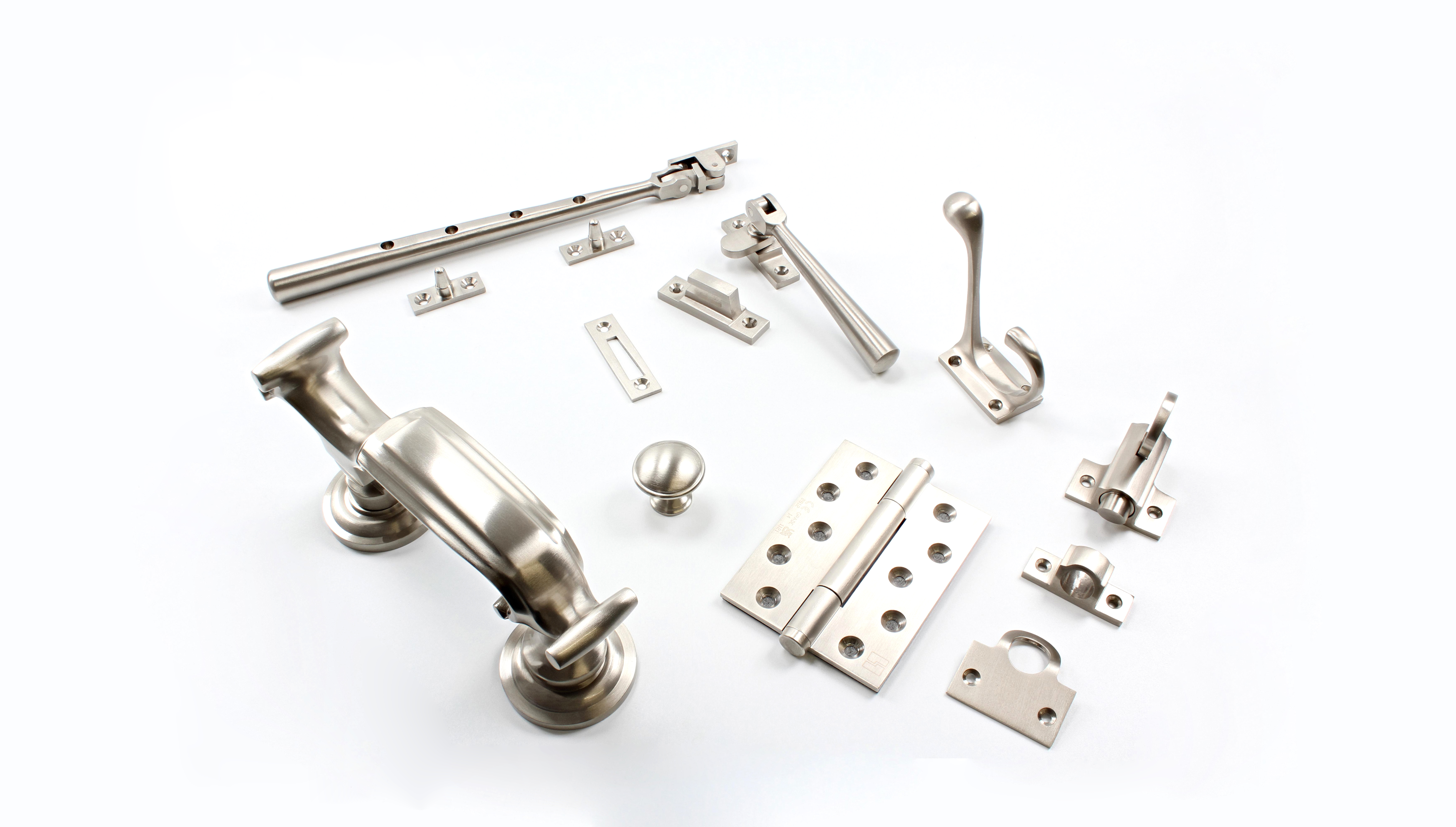

What colour is Satin Nickel?

Satin Nickel is a warm grey colour with a very slight golden tint and visible brush marks in the surface of the item. Satin Nickel is very popular with architects and designers for being softer and less harsh then Satin Chrome. As the satin nickel ages a patina forms over the nickel causing it to look slightly "cloudy" making the Satin Nickel an even softer finish.

Are there any other colours similar to Satin Nickel?

Yes, if you can’t find the item you are looking for in Satin Nickel, the next closest finishes are Satin Stainless Steel, Satin Chrome or Matt Chrome.

Satin Chrome SatinStainless Steel Satin Nickel

As you can see from the above images, Satin Nickel is a grey colour with a golden tint, Satin Stainless Steel also has a very slight golden tint making it a very close match. Satin Chrome and Matt Chrome are more of a grey colour with a blue tint to them.

What are Satin Nickel products made from?

Most of the Satin Nickel items we sell are made from solid brass. Traditionally brass has been the best base material for nickeling on to, as the brass could be highly polished to produce a nice smooth item, then easily satinised to produce the brushed satin look. The satin item is then electro-plated in Nickel, producing a dull grey colour with a slight golden tint.

In recent years as raw material prices have risen the cost of brass has increased massively, manufacturers have had to try and source alternative base materials for nickeling on to, to help keep their products competitively priced. We’re now seeing Satin Nickel plated on to base materials of Zinc Alloy, Mazac, Aluminium, and Stainless Steel with very good results that are almost identical to plating on to brass.

Please check individual products to see what base material they are made from.

How is the Satin Nickel finish produced?

Satin Nickel is an electro plated finish. Electro-plating is the process for producing electro deposited finishes on to a metal surface, commonly known as “plating.” The process consists of passing an electric current between an anode and a cathode through a chemical solution. If you liken the set up to a car battery the anode is “positive” and the cathode is “negative.”

In the nickel plating process the anode is a piece of nickel rod and the cathode is the product being plated. The nickel rod and the product are lowered into a vat containing an electrolyte solution. The power is turned on and the nickel starts to dissolve into the electrolyte solution. At the same time the current is traveling from the positive anode (the nickel rod) through the solution "carrying" the dissolved nickel particles and depositing them as a thin layer on to the negative cathode (the product.)

Before the nickel plating stage the base material of the product must be satinised ("brushed") to produce the dull, satin effect. Underneath the nickel plated layer will be an electro-plated layer of copper which acts as a “primer coat” to help ensure the nickel is as hard-wearing and long lasting as possible.

Occasionally some manufacturers will then lacquer the satin nickel to seal and maintain the finish.

Are all Satin Nickel items the same colour?

No, due to the random process of satinising, Different product ranges will have a slightly different brushed pattern and colouring depending on how long and how hard it has been "brushed."

Will the Satin Nickel fade or discolour?

Yes, as the Satin Nickel ages a patina forms over the nickel causing it to look slightly "cloudy" making the Satin Nickel an even softer finish.

Note - (Some manufacturers lacquer their Satin Nickel products to hold original finish for as long as possible.)

Are Satin Nickel products suitable for outside use?

Yes, the nickel plating process is hard-wearing and will help protect the base material well. The best Satin Nickel products to use externally are the items with a base material of brass.

Satin Nickel products fitted externally must be cleaned regularly to keep the finish looking its best. With so much pollution in the air and acidity in the rain, if you don’t clean externally fitted items you will find the nickel will start to “pit” and eventually start to wear off. A quick regular clean with a soft cloth and wax based furniture polish to remove dirt and water marks will ensure your Satin Nickel products will look as good as new for a very long time.

How to clean and maintain Satin Nickel products?

Satin Nickel products should be cleaned regularly with a soft cloth and wiped over with a wax based furniture polish ideally beeswax, but products like “Pledge” and “Mr Sheen” work well too. For stubborn stains warm soapy water can also be used.

For items fitted outside if you start to see pitting marks in the nickel a metal polish such as “Brasso” or “Peek” can be used to polish the layer of nickel.

Regular cleaning to remove dirt, finger prints and water marks will ensure your Satin Nickel products will last for a very long time.

What products are readily available in Satin Nickel?

Most of the companies we deal with manufacture and supply Satin Nickel products